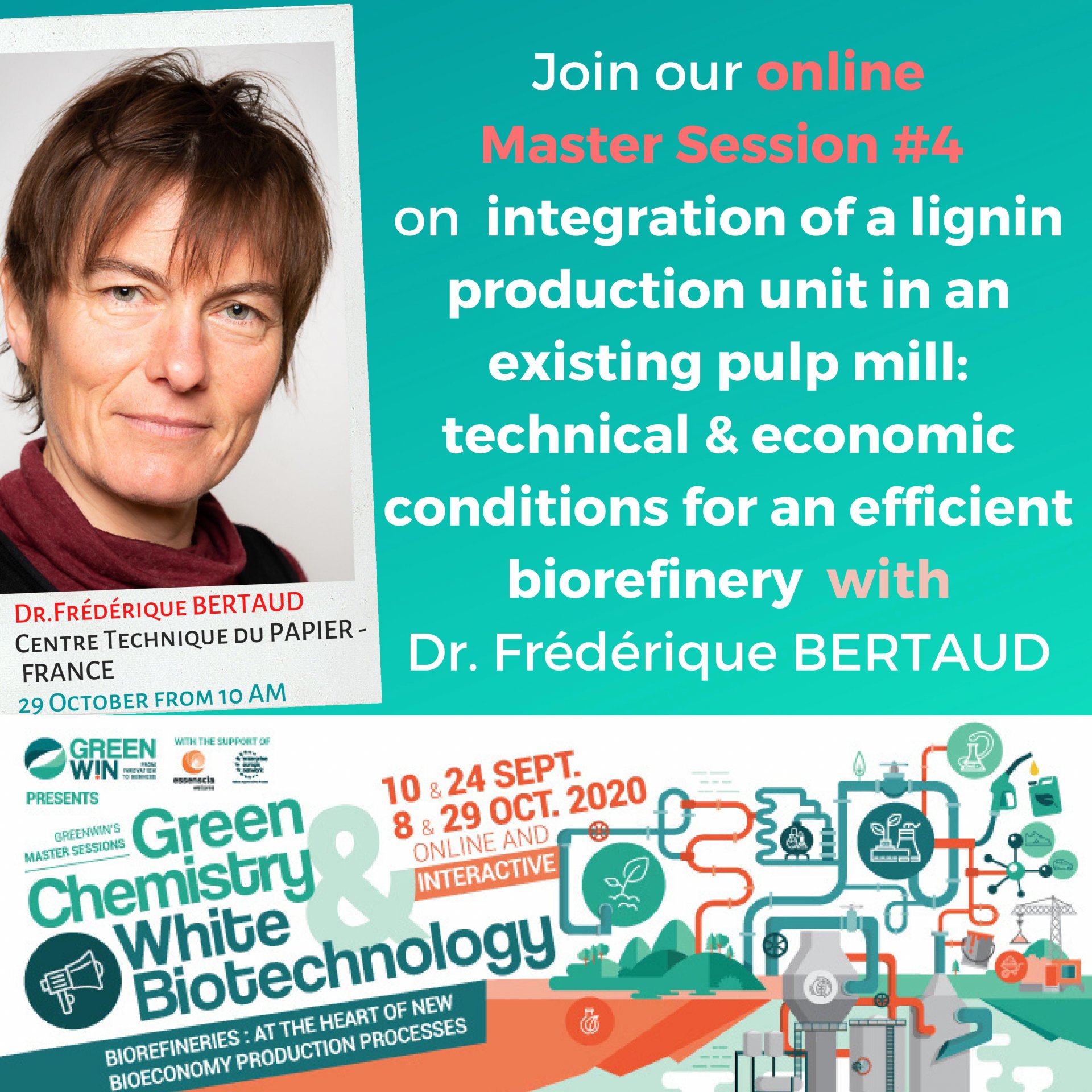

Meet Dr Frédérique BERTAUD, from Centre Technique du Papier - France, at our online Master Session #4 on 29 October from 10AM

Since obtaining her PhD in ‘Valorisation of Lignocellulosics by oxidation’ from Université de Poitiers, and following a Postdoc position working on ‘Wood chemistry and analyses’ at Abo Akademi in Finland, Dr Frédérique BERTAUD has been a scientist at CTP (Centre Technique du Papier in Grenoble) for over 18 years. She specialises in the field of wood and pulp chemistry, particularly the ‘Development of Biorefinery applied to pulp mills’. More specifically, she is responsible for the valorisation of pulp mill by-products, such as wood extractives and lignin, covering their extraction from lab to semi-pilot scale, and their analyses. In connection with pulp mills, she has developed modelling tools to simulate extraction units in an existing pulp line, and establish the technical and economic impacts of such valorisation.

Topic title:

Integration of a lignin production unit in an existing pulp mill: technical and economic conditions for an efficient biorefinery

Abstract

Lignins are aromatic natural polymers which, along with cellulose and hemicelluloses, compose the cell walls of wood. During chemical pulping, lignins are partially degraded and solubilised in cooking liquor. Currently, lignins in black liquor are generally burned in order to contribute to a mill’s self-sufficiency in energy. At present, only 1 million tonnes of lignin are available in the world per year, the main source coming from the acid sulphite process that leads to lignosulfonates. The pulp and paper industry, with 183.8 million tonnes of pulp produced worldwide, is a good potential source of 50 to 70 million tonnes of lignins. Within the framework of the development of bio-sourced products made from renewable raw materials, lignins are interesting ‘green’ alternatives for the production of aromatic and carbon products. The global lignin market is expected to significantly expand with the recent and forthcoming creation of new production lines combined with new valorisation routes. This study aims to establish the technical and economic impacts of lignin extraction in existing pulp mills through the development of modelling tools based on industrial and experimental data.

Each Master Session will take up to 2 hours from 10 AM till noon and will be themed according to the following specific subjects:

Session #1: New (bio)resources – 10 September 2020

Session #2: New (bio)products – 24 September 2020

Session #3: New technologies > industrial micro bio network – 8 October 2020

Session #4: New technologies > enzymatic and extraction technologies – 29 October 2020

The detailed programme and list of speakers is available on the PDF here below.

How to register?

You can register for one or several sessions, à la carte so to speak. Should you opt for a registration to all sessions (full menu formula), a discount will be applied.

Pricing (VAT excluded):

> Members*: €50.00 per Master Session & €170 for the whole series of 4 sessions

> Non-Members : €75.00 per Master Session & €250.00 for the whole series of 4 sessions

(*) fee applicable for all members of the Walloon Innovation Clusters. If you are member of another Walloon Innovation Cluster (Wagralim, BioWin, Logistics In Wallonia, Mecatech, SkyWin), please, send a proof of your membership to the following address: compta@greenwin.be

Payment has to be made via this payment platform prior to registration process.

Cancellation policy: Please note that no refund will be made for cancellation. However, the registered person may be replaced. In that case, GreenWin has to be informed as soon as possible, and provided with the full details of the surrogate participant, at the following address: conferences@greenwin.be

08/10/2020