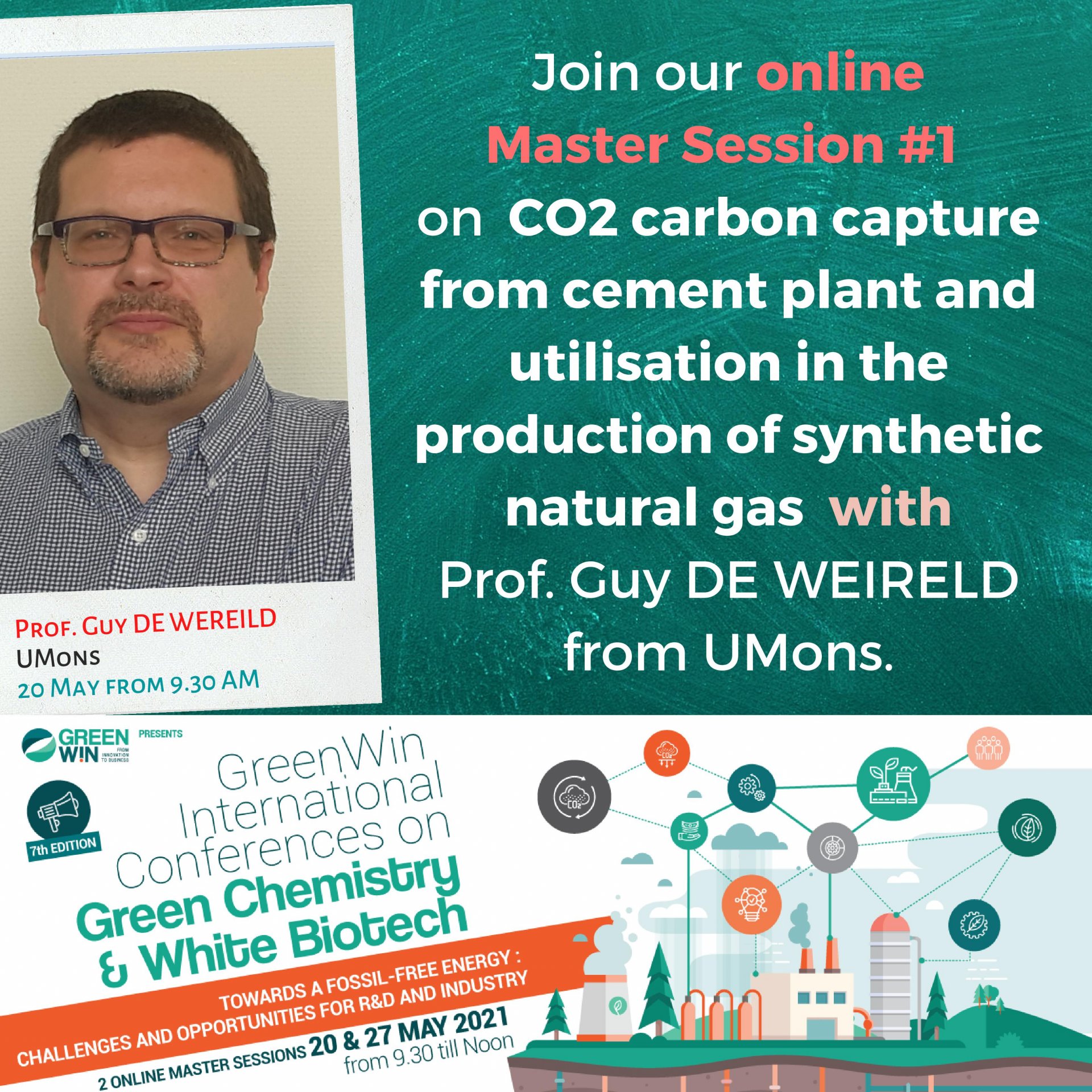

How does CCU from cement plant and utilisation help producing synthetic natural gas? Prof. Guy DE WEREILD from UMons knows all about it!

Carbon Capture Utilisation and Storage (CCUS) technologies are receiving increased interest. Within this context, Power-to-Gas technologies (PtG) are very promising, allowing for the storage of excess renewable electricity, and valorising captured CO2 for the production of Synthetic Natural Gas (SNG), amongst others.

The aim of this work is to evaluate the interest of an integrated PtG system converting CO2 from cement plant flue gases. More specifically, the process chain implemented (the CO2 capture and CO2 catalytic conversion into Synthetic Natural Gas (SNG) process, using H2 produced by electrolysis) is designed to capture almost 1 ton per hour of CO2 emanating from a conventional cement plant equipped with the best available techniques. Economic assessment and Life Cycle Analysis are undertaken to estimate the investment and operational costs of the process chain, and to identify the main environmental hotspots (the net CO2 emissions into the atmosphere and the contribution to fossil depletion) while comparing two scenarios (cement plant with and without the integrated CO2 capture-conversion process).

Guy DE WEIRELD is a professor in chemical thermodynamics, the environment, industrial processes, and sustainable development at the Faculty of Engineering of the University of Mons. His main research field is adsorption in porous materials and catalysis. He has experience in CO2 capture, gas separation, gas purification (removing of acid compounds from natural gas, VOC from exhaust air) and CO2 conversion to fuel, as well as in techno-economic and environmental assessments in the field of carbon capture, utilisation and storage. Since 2019 he has been the coordinator of the H2020-MOF4AIR project: Metal Organic Frameworks for carbon dioxide Adsorption processes in power production and energy Intensive industries.

Each Master Session will take up to 2 hours from 9.30AM till noon and will be themed according to the following specific subjects:

Session #1: CCU – Mineralisation – Hydrogen Programme: 20 May

Session #2: Energy storage and batteries recycling Programme: 27 May 2021

The detailed programme and list of speakers are available here.

How to register?

You can register for one or both sessions, à la carte so to speak. Should you opt for a registration to both sessions (full menu formula), a discount will be applied.

Pricing (VAT excluded):

> Members*: €100.00 per Master Session & €175 for both sessions

> Non-Members: €140.00 per Master Session & €245.00 for both sessions

> Students: FREE

Payment is to be made via this payment platform prior to registration process.

Cancellation policy: Please note that no refund will be made for cancellation. However, the registered person may be replaced. In that case, GreenWin has to be informed as soon as possible, and provided with the full details of the surrogate participant, at the following address: conferences@greenwin.be

(*) fee applicable for all members of the Walloon Innovation Clusters. If you are member of another Walloon Innovation Cluster (Wagralim, BioWin, Logistics In Wallonia, MecaTech, Skywin), please, send a proof of your membership to the following address: compta@greenwin.be

Organised by GreenWin in partnership with Wallonia.be , Wallonia region, essenscia Wallonie, John Cockerill, De Smet Engineers & Contractors & Fluxys .

Special thanks to:

Carmeuse, Syngulon , TWEED Cluster , ULB, UCLouvain, ULiège, Gembloux AgroBioTech, UNamur and UMons for their support.

20/05/2021